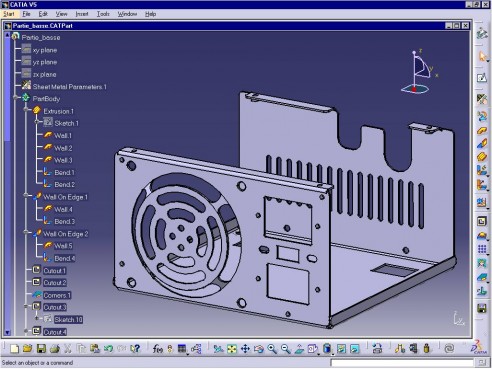

The generative sheetmetal design workbench introduces some new and enhanced functionality to the creation of sheet metal parts.

Difference between sheet metal design and generative sheet metal design.

Whereas cold rolled steel is processed in cold reduction mills followed by annealing and tempering.

Gsd belongs to shape design styling domain and as an example it is inside hd2 catia hybrid design 2 configuration on p2 platform.

What i was told when i participate the testsession for v5r13 at dassault was that the old sheet metal algorithms had serious performance problem.

Additionally in the new versions the generative sheet design toolbar is replaced with several toolbars this provides logical grouping of functions for enhanced accessibility.

In a sheet metal design specifying hole sizes locations and their alignment is critical.

How to switch from catia surface design to part design and sheet metal design.

Generative sheet metal parameters overview.

An intermediate product called gs1 catia generative shape design 1 exists and is similar to gsd with a reduced number of commands comparing to gsd and a reduced number of options inside the same command.

Catia difference between part design and surface design.

It is possible to declare a variable to hide the old sheet metal.

Hot rolled steel involves rolling the steel sheets above re crystallization temperatures.

Generative sheet metal design overview.

The major d ifference between hot rolled and cold rolled steel is the way they are processed.

It is always better to specify hole diameters that are greater than the sheet s thickness t.

Dassault has build the generative sheet metal with the algorithms from aerospace sheet metal.

Parameter standards help you enforce standard techniques and practices used when creating sheet metal features by simplifying how one defines the feature parameters therefore streamlining the design process.

I understand that creo is considered high end and that solidworks is more middle of the road but their company offers a high end called catia.

You can also verify sheet metal features or the entire part against these standards.

The generative sheetmetal design workbench is a new generation product offering an intuitive and flexible user interface.

It provides an associative feature based modeling making it possible to design sheet metal parts in concurrent engineering between the unfolded or folded part representation.

I ve been asked to do a quick supplemental sheet metal design comparison between solidworks and creo 2 0 for my cad class.

To know various materials used to manufacture sheet metal parts.