If you are placing sheet metal over an existing roof it is important to remember that certain metals when placed in contact with others can generate an electrolytic reaction that will cause the metals to corrode.

Disadvantages of sheet metal working.

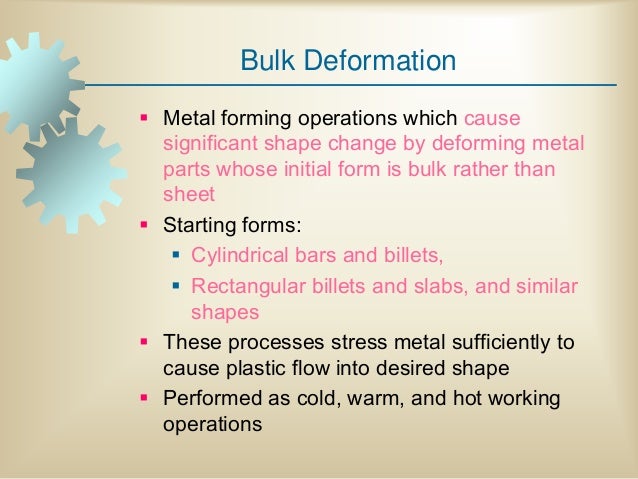

Sheet metal working process 2 17 2016 compiled edited by sivaraman velmurugan 33 disadvantages of hot working lower dimensional accuracy higher total energy required which is the sum of the thermal energy needed to heat the workpiece energy to deform the metal work surface oxidation scale thus poorer surface finish shorter tool life.

It produces good surface finish.

Another potential danger of sheet metal fabrication that employees need to be aware of is the potential for.

Sheet metal forming process advantages and disadvantages 1.

Despite the pros the metal shearing process also has some notable disadvantages.

Shearing is less than ideal with harder metals.

A lesser known danger of working with sheet metal is the potential for breathing in tiny.

Top benefits of using sheet metal in construction 25 april 2015.

This process is for long parts with constant complex cross sections.

There are several processes involved such as the stretch forming roll forming stamping drawing and so on.

But sheet metal isn t only used in industrial situations we find it.

Stretch forming can be used to produce large parts with shallow contours but it is only suitable.

Sheet metal is one of the most versatile and widely used construction materials with applications in just about every industry imaginable from mining construction farming catering hospitality shipping manufacturing aviation medical and transport.

Sheet metal forming process advantages and disadvantages 1.

A disadvantage of air bending is that because the sheet does not stay in full contact with the dies it is not as precise as some other methods and stroke depth must be kept very accurate.

Dangers of working with sheet metal skin burns.

Breathing in sheet metal dust.

Working with sheet metal is not always the easiest and the roofing installation process itself can be quite challenging.

This process is for long parts with constant complex cross sections.

It produces good surface finish.

There is no blanket rule in deciding whether or not a particular sheet metal stamping design is perfect or there are certain disadvantages to it.